- Tire Shredding & Recycling

- Industrial Rubber Shredding

- Electronic Scrap Shredding

- Hazardous Waste Shredding

- Non-Ferrous Scrap Metal Shredding & Recycling

- Ferrous Scrap Metal Shredding & Recycling

- Waste-to-Energy Recycling

- Industrial Paper Shredding & Recycling

- Industrial Plastics Shredding

- Solid Waste Shredding

- White Goods Recycling

- Other Applications

Tire Shredders & Recycling Equipment

Granutech Saturn Systems offers a complete line of tire shredders and recycling equipment designed to process scrap tires for recycling and repurposing for a variety of applications.

With over 50 years of experience developing equipment to provide high-quality rubber from scrap tires, Saturn® tire shredders and complementary machines provide cost-effective options for shredding tires, separating rubber from steel, and generating granulated or powdered rubber for recycling operations and clean steel. Our staff has decades of experience in the scrap tire industry, and we’ll make sure that the tire shredder equipment we provide you will meet your specific recycling requirements.

Scrap Tire Shredding Solutions

Our line of tire shredders and recycling equipment includes a wide range of custom shredders, grinders, and granulators, Excelling in efficiency, durability, and reliability, our equipment can process tires to generate clean rubber crumb, and the finest, cleanest product powder rubber for use in a variety of applications including:

- Crumb rubber for playground surfaces

- Rubber powder for sport/turf fields

- Rubberized asphalt paving (rubber-modified asphalt*)

- Rubber powder for manufacturing molded or extruded rubber parts

*Click here for related application articles

Product Solutions

- Granutech Tire Recycling Systems

- Saturn® Grizzly Super 80

- Saturn® Powderizers

- Saturn® G-4X Refiner Mill

Recycling Systems

Incorporating shredders, granulators and refiner mills/powderizers

Convert whole scrap tire into high quality crumb rubber with Granutech’s tire granulation systems. Our complete processing systems have a proven track record of providing the cleanest crumb rubber in the industry, with precise sizing control and the widest range of output sizes available. Our custom designs use a variety of conveying and processing technologies to minimize product loss, increase productivity and maintain a clean operating environment. Our crumb rubber systems can generate crumb rubber in the size required for your recycling product, whether it is coarse rubber for playgrounds or finer crumb for artificial turf.

Visit our Recycling Systems page for full details on 2, 3, and 4 stage systems! Learn More »

Saturn® Grizzly Super 80

10 tons per hour

The Grizzly separates rubber and steel during processing while producing incredibly clean rubber. Our unique single-rotor design provides efficient size reduction. Adjustable screen sizes provide flexibility in the final product size, with ranges from 1/2" minus to 1-inch minus, or larger. By producing smaller, more consistent material, the Grizzly improves the performance of downstream equipment, or can replace it entirely. With consistent sizing of the rubber, the resulting rubber is an economic material for use in molding and extruding processes. Learn More »

Saturn® Powderizers

Using wire-free 1/4" tire chips, Granutech’s Powderizers can produce output sizes from 5/32 to 30 mesh, depending on screen size. They are high output machinery, with rates ranging from 12 pounds per minute to 30 pounds per minute, depending on the screen selection and final output size. Powderized rubber is used for molded and extruded parts. Learn More »

Saturn® Refiner Mills

Our next generation G-4X mill features higher processing speeds of 3 tons per hour and can produce 10 mesh through 80 mesh rubber powder using clean stock from granulator or Powderizer systems, further refining the rubber for high quality rubber material. In addition, the sealed roller bearing design eliminates the need for continuous lubrication, saving up to $25,000 a year in consumables—and reduced energy consumption due to more efficient operation.

Recycling scrap tires requires machinery that can efficiently produce clean rubber in the size that is required for the intended use of the recycled material. Granutech has the experience and knowledge to provide you with the custom solutions to meet your application requirements, allowing you to efficiently and cost-effectively recycle tires. Learn More »

See Our Brochure On Complete Turnkey Solutions

Tire Shredders

Our line of tire shredders and scrap tire shredding and recycling equipment process a variety of tires:

- Car Tires

- Truck Tires

- Passenger Tires

- Agricultural Tires

- Tractor Tires

- Off Road Tires (OTR)

- Forklift Tires

- Mining Equipment Tires

- Aircraft Tires

Tire Shredding & Tire Recycling Systems

Options for our 2, 3, and 4-stage scrap tire shredding and recycling equipment systems include:

- 2-stage system -- reduces whole tires to steel-free mulch material or a low steel fuel quality material. This system solution would typically be comprised of the Saturn Shredder series (dual or quad shaft) plus a grinder (Saturn Grizzly Series- M80 or S80 models).

- 3-stage system -- 2-stage system plus a granulator or a refiner mill. For .5-3mm material output, you would add a Saturn G-4X Refiner Mill.

- 4-stage system -- would reduce all material to 1-3mm if with the addition of a Granutech Powderizer, or all under 1mm with the Saturn G-4X refiner mill.

Tire Shredding Systems Benefits

At Granutech Systems, our tire recycling systems offer a number of advantages that differentiate our tire shredding processes from those in the industry. Here are some of our key benefits:

- Cleanest crumb rubber in the industry

- Precise sizing control

- Minimized product loss

- Efficient size reduction

- Consistency of rubber sizing

- High output machinery

- High processing speeds

- Reduced energy consumption

Come join our Online Weibold webinar —featuring Granutech

“Reliability and Profitability in Tyre Recycling”

Tire Recycling Systems

Tire Recycling Systems

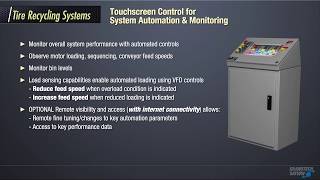

Granutech-Saturn TRS Control Station

Granutech-Saturn TRS Control Station

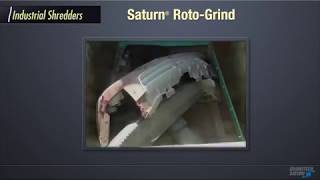

Saturn Grinders & Granulators

Saturn Grinders & Granulators

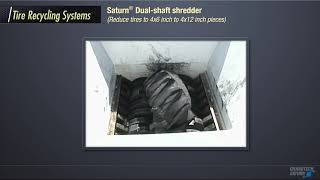

Saturn Dual Shaft Shredder - Tires

Saturn Dual Shaft Shredder - Tires

Shredders

Shredders

Powderizers & Refiner Mills

Powderizers & Refiner Mills

Model 60-44BGHT - Truck Tires

Model 60-44BGHT - Truck Tires

Two Stage Tire Processing - Model 60-44BGHT and Grizzly Super 80

Two Stage Tire Processing - Model 60-44BGHT and Grizzly Super 80

Model 72-44BGHT Mobile Shredder - Tires

Model 72-44BGHT Mobile Shredder - Tires

Grizzly Super 80 with a 1-1/8" screen - Tire Shreds

Grizzly Super 80 with a 1-1/8" screen - Tire Shreds

Click here to submit a Request for Quote or call us today at 877.582.7800